Products

Categories

Message

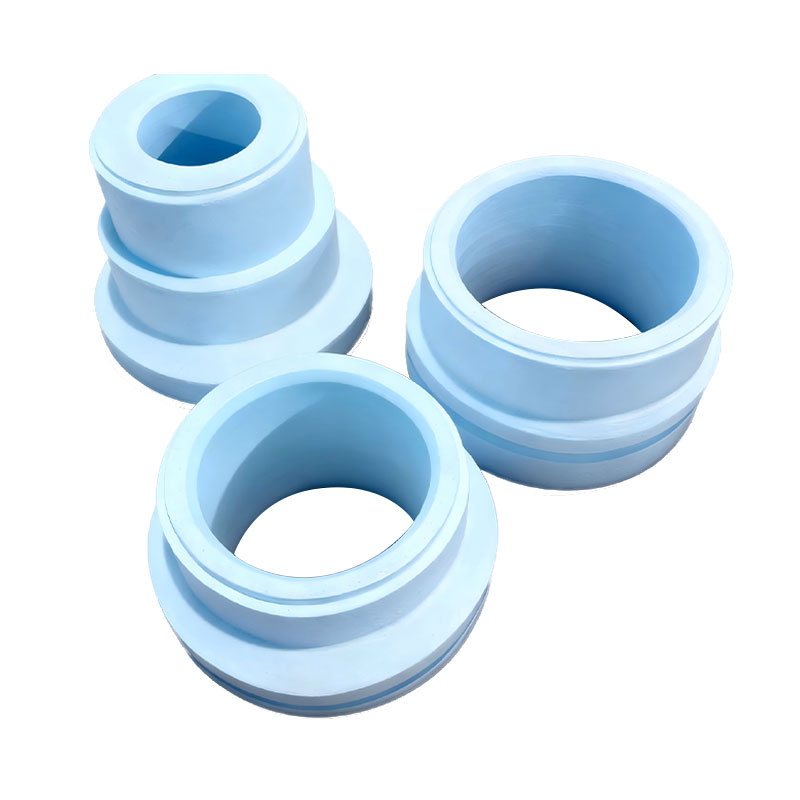

Hot-top Casting Guide Pipe

Products Description

About This Project

Hot-top Casting Guide Pipe

Shandong Jinyi New Material Co., Ltd. is a high-tech manufacturer specializing in R&D and production of molten aluminum flow control systems. Since its establishment, we have been dedicated to developing precision casting accessories, with hot-top casting guide pipe as the core product. It is synergistically used with casting sprue bush, distribution plate, graphite ring and distribution launder to achieve stable molten aluminum transmission, and is especially compatible with Wagstaff air slip casting units. Our flow control series has gained wide recognition in high-value-added aluminum casting fields.

Core Material & Performance

Shandong Jinyi’s hot-top casting guide pipe adopts dual-material system to meet diverse application demands:

- High Silicon Melting 140 Material: Optimized for high-frequency casting scenarios, featuring extreme corrosion resistance and thermal stability

- Al-Si Alloy Material: Ideal for medium-load casting, balancing cost-effectiveness and performance

Both materials are non-polluting to molten aluminum, ensuring alloy purity, and exhibit excellent compatibility with BN (boron nitride) coating for anti-sticking effect.

Technical Parameters (High Silicon 140 Model)

| Item | Index |

| Density | 1.4-1.5 g/cm³ |

| Compression Strength | 15-16 Mpa |

| Thermal Expansivity | 4-4.5×10⁻⁶/℃ |

| Max Working Temperature | >1000℃ |

| Service Life | 450-800 casting cycles |

Application Scenarios

- Hot-top casting process of aluminum ingots, wire rods and high-precision profiles

- Matching with 3-20 inch diameter aluminum alloy casting (compatible with common alloy specifications)

- Adaptation to high-pressure aluminum casting equipment (resistant to casting pressure up to 80 tons)

- Precision casting of high-value-added aluminum products (aerospace, automotive lightweight parts)

Product Advantages

- Superior Material Performance: High hardness, erosion resistance and thermal shock resistance; smooth surface avoids molten aluminum turbulence

- Alloy Purity Guarantee: Non-peeling structure prevents material contamination, improving aluminum alloy qualification rate by ≥15%

- Cost Efficiency: Long service life (4-8 times that of ordinary silica products) and low maintenance cost

- Energy-saving Design: Optimized flow channel reduces heat loss; compatible with BN coating for quick demolding

Specification & Package

| Item | Standard Specification | Customization | Package |

| Guide Pipe | Length: 200-800mm | As drawing | 30pieces/carton |

| Inner Diameter: 25-100mm | Custom packaging available |

Installation & Operation Instructions

- Component Matching: Select guide pipe, sprue bush and distribution plate according to alloy diameter and casting equipment model

- Assembly Requirement: Install distribution plate and launder above the platform; fix guide pipe, transition plate and graphite ring below. Ensure all parts are smooth, undamaged and seamless

- Sealing & Insulation: Seal gaps with ceramic fiber blanket/paper at connections to prevent heat loss

- Preheating Procedure: Uniformly preheat the casting platform to 260℃-350℃ after assembly. Use flame heating if no electric heating (avoid direct flame on lining) to remove crystal water