Products

Categories

Message

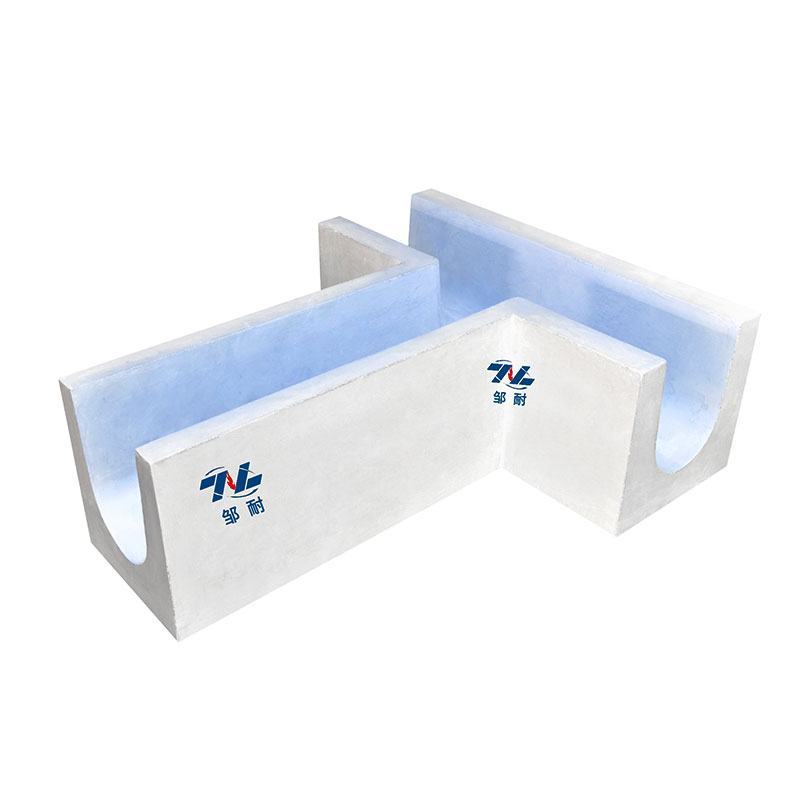

Integrated aluminum liquid chute

Products Description

Integrated aluminum liquid chute

Regarding this project

Shandong Jinyi New Material Co., Ltd. (abbreviated as JINYI), a key enterprise in China’s molten aluminum purification equipment industry since 2014, focuses on the R&D, production, and system integration of integrated aluminum liquid launder systems. As a core part of JINYI’s “one-stop molten aluminum purification solution,” this launder system is designed to match the company’s degassing units, plate-type filters, and ceramic foam filters—realizing seamless connection between molten aluminum transportation, purification, and casting. With proprietary high-silicon material technology and precision manufacturing processes, JINYI’s launder systems have been applied in high-end aluminum processing fields such as automotive lightweight parts, aerospace components, and electronic aluminum casings, winning recognition for stable performance and long service life.

Core Components of JINYI Aluminum Liquid Launder System

The system adopts a modular and detachable design, facilitating on-site installation, maintenance, and replacement of parts. Key components include:

- Steel Casing

- Material: High-strength Q235B carbon steel, welded with a fully enclosed structure to prevent molten aluminum leakage.

- Anti-corrosion Treatment: Two-step process of phosphating (for rust prevention) and epoxy resin coating (for chemical corrosion resistance), ensuring no rusting even in high-temperature workshop environments for 5+ years.

- Connection Design: Equipped with standardized flange interfaces and quick-lock fasteners, compatible with JINYI’s degassing units (15-65 MT/H) and plate-type filters (15-26in), reducing on-site assembly time by 40%.

- High-Silicon Lining

- Manufacturing Process: Produced via JINYI’s “vacuum pressure sintering technology,” using high-purity silica (SiO₂ content ≥98.5%) mixed with rare earth composite additives. This process enhances the lining’s compactness, reducing porosity to ≤2%.

- Performance Advantages: Corrosion resistance to molten aluminum (no reaction with Al, Mg, Si in alloys), non-stick aluminum surface (paired with JINYI’s BN coating, adhesion rate ≤0.5%), and thermal shock resistance (no cracking when temperature changes by 300℃ within 1 hour).

- Customization: Supports independent production of linings (thickness 50-150mm) according to customer’s launder width, curvature, and flow requirements.

- Ceramic Fiber Insulation Cover

- Structure: Inner layer (alumina-silica ceramic fiber blanket, density 220kg/m³) + outer layer (304 stainless steel sheet, thickness 1.2mm), with a flip-up hinge design for easy opening (opening angle ≥120°).

- Thermal Insulation Effect: Heat loss rate ≤5% per hour, ensuring molten aluminum temperature drop is controlled within 2℃ per meter of launder length—lower than the industry average of 3-5℃/m.

- Safety Design: Equipped with a high-temperature-resistant sealing strip (silicone rubber + glass fiber) at the edge, preventing hot air leakage and reducing workshop temperature rise.

Application Scenarios

JINYI’s aluminum liquid launder system is installed between upstream melting equipment (holding furnaces, homogenizing furnaces) and downstream processing equipment (degassing units, filters, casting machines), mainly used for:

- Transportation of molten aluminum between furnaces (e.g., from holding furnace to purification furnace);

- Connection between purification equipment (degassing/filtration) and casting platforms (e.g., for aluminum foil casting, ingot casting);

- High-precision casting lines (e.g., computer hard drive aluminum casings, micron-grade aluminum foil, jet turbine engine fan blades, printing PS baseboards).

The system effectively avoids secondary contamination of molten aluminum during transportation and ensures stable temperature, laying a foundation for high-quality aluminum alloy production.

Core Performance Advantages

- Ultra-Low Temperature Drop

With the composite insulation structure of “high-silicon lining + ceramic fiber cover,” the molten aluminum temperature drop is ≤2℃ per meter—even in long-distance transportation (5-10m), the temperature can be maintained within the required casting range (720-780℃).

- Long Service Life

The high-silicon lining has strong resistance to molten aluminum erosion and thermal shock, with a service life of ≥1 year under 24/7 continuous operation; the steel casing and insulation cover have a service life of ≥3 years (excluding wear parts such as sealing strips).

- High Compatibility

Standardized interfaces match JINYI’s full range of purification equipment, and can also be adapted to third-party degassing/filter units by adjusting flange sizes—reducing the cost of system transformation for old production lines.

- Easy Maintenance

The detachable insulation cover and independent lining design allow quick replacement of worn parts (lining replacement takes ≤4 hours, 50% faster than traditional launders); the smooth lining surface reduces slag accumulation, lowering daily cleaning workload.

- Environmental Protection & Safety

The high-silicon lining contains no heavy metals (Pb, Cd, Hg) and does not release harmful gases at high temperatures, complying with national environmental protection standards (GB/T 38437-2020); the insulation cover’s sealed design reduces heat radiation, improving workshop operating environment.

Technical Parameters

| Parameter Category | Index Value | Description |

| Lining Density | 1.8-2.0 g/cm³ | Ensures compactness and erosion resistance |

| Rupture Modulus (816℃) | 18.8-19.8 MPa | Prevents lining cracking under high temperature |

| Thermal Expansivity (680℃) | 1.56×10⁻⁶ K⁻¹ | Reduces thermal stress damage |

| Thermal Conductivity (540℃) | 0.8-0.95 W/(k·m) | Low heat transfer, good insulation effect |

| Max Operating Temperature | 1340℃ | Suitable for high-temperature molten aluminum (up to 850℃ for casting) |

| Lining Surface Roughness | Ra ≤1.6 μm | Smooth surface, reducing aluminum adhesion |

| Temperature Drop Rate | ≤2℃/m | Key index for stable molten aluminum quality |

Dimension Specifications

1. Standard Dimensions

| Launder Type | Lining Length (mm) | Lining Width (mm) | Lining Thickness (mm) | Overall Length (mm) | Insulation Cover Width (mm) |

| Short Launder | 500, 800, 1000 | 150-300 (custom) | 50-80 | Lining length + 100 | Lining width + 40 |

| Medium Launder | 1200, 1500, 1800 | 200-400 (custom) | 60-100 | Lining length + 120 | Lining width + 50 |

| Long Launder | 2000, 2500, 3000 | 250-500 (custom) | 80-150 | Lining length + 150 | Lining width + 60 |

2. Custom Dimensions

- Curved Launders: Radius ≥1000mm, suitable for corner transportation in production lines;

- Special-Shaped Launders: Trapezoidal, U-shaped, or with diversion grooves, designed according to customer’s site layout and flow requirements.

Operating Instructions

1. Installation Requirements

- Place the launder on a level concrete foundation or steel bracket, ensuring horizontal error ≤0.5mm/m (use a level to calibrate);

- Connect the launder to upstream/downstream equipment via flanges, and install high-temperature-resistant gaskets (ceramic fiber) between interfaces to prevent molten aluminum leakage;

- Check the lining for cracks, gaps, or foreign matter—if any, repair with JINYI’s special high-silicon mortar or replace the lining.

2. Preheating Process

Preheating is critical to remove adsorbed crystal water from the lining and avoid cracking. Two methods are available:

(1) Electric Heating (Recommended)

- Use JINYI’s matching electric heating rods (power 2-5kW) installed in the launder’s heating holes;

- Temperature rise curve: Ambient → 200℃ (2℃/min, hold 2h) → 400℃ (1.5℃/min, hold 2h) → 600-800℃ (1℃/min, hold 3h);

- After preheating, cool down to 600-650℃ before introducing molten aluminum.

(2) Flame Heating (On-Site Backup)

- Use a low-pressure natural gas burner (flame length ≤300mm), avoid direct flame contact with the lining;

- Flame control: Red weak flame (300-400℃, 2h) → Yellow medium flame (400-600℃, 3h) → Blue strong flame (600-800℃, 2h);

- Monitor temperature with a thermocouple (inserted 50mm into the lining) to prevent overheating.

3. Operation & Monitoring

- Control molten aluminum flow rate: 0.5-1.0 m/s (adjust via upstream valve), avoid excessive flow causing lining erosion;

- Check temperature drop every 30 minutes (measure inlet/outlet temperature with an infrared thermometer), if drop exceeds 2℃/m, inspect the insulation cover’s seal;

- Remove surface slag through the insulation cover’s slag removal port every 1-2 hours, use a wooden scraper (no metal tools to avoid scratching the lining).

4. Post-Operation Shutdown

- After casting, drain residual molten aluminum completely (use a dedicated drainage trough);

- Cool the launder to ≤200℃ naturally (no forced cooling), then clean the lining surface with compressed air;

- Apply a thin layer of JINYI’s BN coating (thickness 0.1-0.2mm) to the lining surface to protect it for next use.

Service Life & Warranty

| Component | Service Life (Under Normal Use) | Warranty Period | Coverage Scope |

| High-Silicon Lining | ≥1 year | 6 months | Manufacturing defects (cracks, peeling) |

| Steel Casing | ≥3 years | 1 year | Structural deformation, coating peeling |

| Ceramic Fiber Insulation Cover | ≥3 years | 1 year | Fiber shedding, stainless steel rusting |

| Wear Parts (Sealing Strips, Fasteners) | 6 months | 3 months | Deterioration, damage |

Maintenance Schedule

To extend the system’s service life, follow the maintenance plan below:

| Maintenance Cycle | Work Content |

| Daily | 1. Inspect lining for cracks/slag; 2. Check insulation cover’s seal; 3. Record temperature drop. |

| Weekly | 1. Tighten flange fasteners; 2. Clean heating holes (if electric heating); 3. Replace damaged sealing strips. |

| Monthly | 1. Apply BN coating to the lining; 2. Test thermal conductivity of the insulation cover; 3. Calibrate temperature measuring equipment. |

| Quarterly | 1. Inspect steel casing for corrosion; 2. Check lining thickness (wear ≤5mm is acceptable); 3. Overhaul the heating system. |

| Annual | 1. Replace the insulation cover’s ceramic fiber blanket; 2. Evaluate lining wear, replace if necessary; 3. Full-system pressure test (to check for leakage). |