Products

Categories

Message

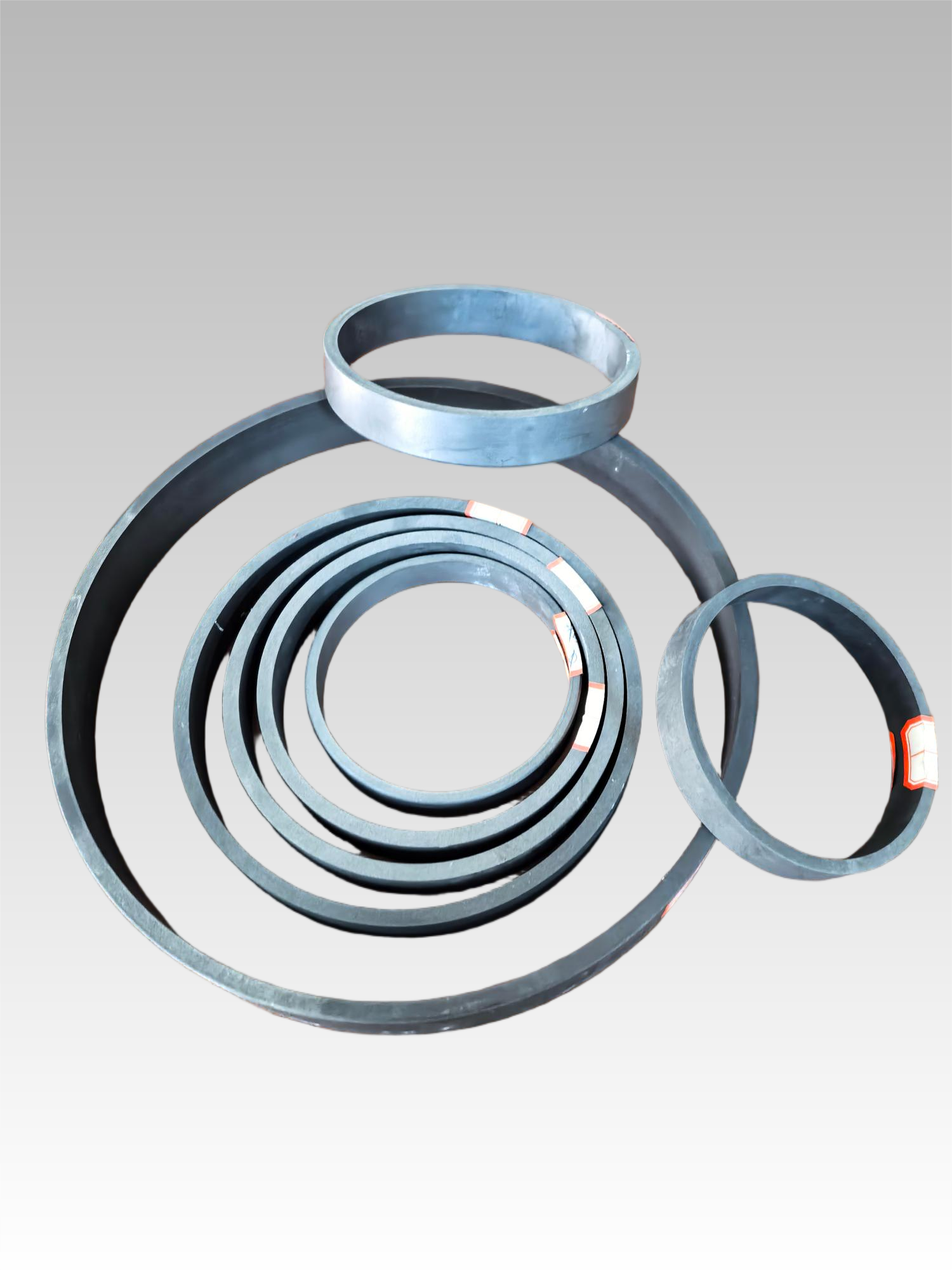

Graphite Ring

Products Description

Shandong Jinyi Hot-top Casting Graphite Ring

1. Product Overview

Shandong Jinyi New Material Co., Ltd. specializes in R&D and production of high-performance components for molten aluminum hot-top casting. The graphite ring, as a core sealing and wear-resistant part in hot-top casting systems, collaborates with transition plates, distribution plates, and casting thimbles to achieve leak-free molten aluminum flow. It is fully compatible with Wagstaff air slip casting units and widely applied in high-end fields such as new energy vehicle aluminum parts, aerospace components, and precision aluminum casting.

2. Core Material & Performance

| Item | Details |

| Material | ≥99.5% high-purity graphite, processed by precision CNC equipment |

| Key Performance | – Excellent corrosion resistance to molten aluminum- High dimensional accuracy (±0.03mm)- Smooth surface (Ra≤0.6μm)- Strong thermal shock resistance |

| Pollution Control | No peeling or impurity release, meeting high-value-added aluminum casting standards |

3. Technical Parameters

| Parameter | Specification |

| Purity | ≥99.5% |

| Density | 1.75-1.85 g/cm³ |

| Compression Strength | ≥20 Mpa |

| Max Working Temperature | 1200℃ |

| Service Life | 800-1200 Casting Cycles |

4. Compatibility & Applications

4.1 Matching Components

Transition plate, distribution plate, casting thimble, distribution launder, casting mold

4.2 Application Scenarios

- Hot-top casting of aluminum ingots and high-precision aluminum rods

- Compatible with 3-20in aluminum alloy diameters

- Suitable for large-scale continuous aluminum casting production lines

5. Product Advantages

- Extended service life: 2-3 times longer than ordinary graphite rings, reducing component replacement frequency

- Quality improvement: Prevents molten aluminum leakage and contamination, enhancing aluminum alloy qualification rate

- Energy efficiency: Optimized structure reduces heat loss during casting

- Low maintenance: Stable performance minimizes post-installation maintenance costs

6. Specifications & Packaging

6.1 Specifications

- Standard: Fits 3-20in aluminum alloy diameters

- Customization: Available according to customer’s equipment drawings or process requirements

6.2 Packaging

- Standard: 25pieces/box (moisture-proof packaging to avoid graphite absorption of water)

- Bulk orders: Custom wooden pallets (anti-collision design for long-distance transportation)

7. Installation Instructions

- Select the graphite ring size matching the alloy diameter and hot-top casting equipment model.

- Install the graphite ring between the transition plate/thimble and the casting platform; ensure the surface is smooth, undamaged, and seamless with adjacent components. Seal edges with ceramic fiber material for thermal insulation.

- After installation, preheat the casting platform uniformly to 260℃-350℃ (to remove adsorbed crystal water); direct flame heating on the graphite ring itself is prohibited.

Contact Information: Shandong Jinyi New Material Co., Ltd. | For customization or technical inquiries, please contact our sales team.