Products

Categories

Message

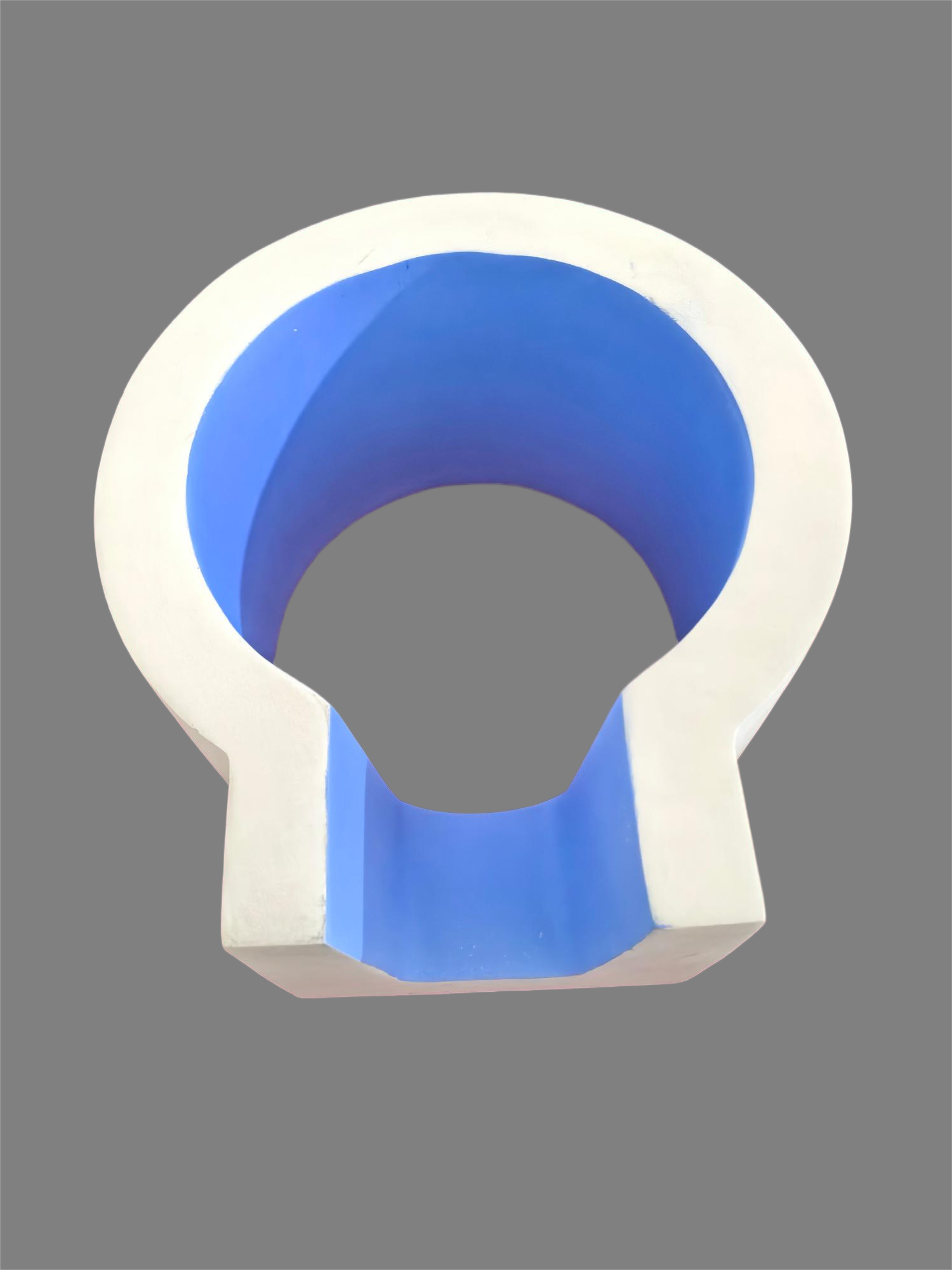

Hot-top Casting Hat Plate

Products Description

About This Project:Hot-top Casting Hat Plate

About This Project

Hot-top Casting Hat Plate

Shandong Jinyi New Material Co., Ltd. is a professional high-tech enterprise focusing on the R&D, production and application of hot-top casting series products for molten aluminum processing. Since its establishment, we have been committed to optimizing molten aluminum flow control in precision casting, with hot-top casting hat plate (hat plate) as a key component of the hot-top casting system. It is used in synergy with casting thimble, distribution plate, transition plate, graphite ring and distribution launder to realize stable, efficient and clean molten aluminum transmission. The whole system is especially compatible with Wagstaff air slip casting units, and has won wide recognition in the high-value-added aluminum casting industry for its reliable performance.

Core Material & Product Performance

Shandong Jinyi’s hot-top casting hat plate is mainly made of high silicon melting 140 material, a premium material tailored for hot-top aluminum casting scenarios, with the following core performance characteristics:

- Corrosion Resistance: Resists long-term erosion by high-temperature molten aluminum, avoiding material dissolution and ensuring no pollution to the aluminum alloy matrix.

- Dimensional Precision: High geometric accuracy, ensuring tight fit with matching components (thimble, distribution plate) to prevent molten aluminum leakage and flow turbulence.

- Surface Quality: Ultra-smooth surface reduces molten aluminum flow resistance, avoids oxide film accumulation, and improves the surface quality of cast aluminum products.

- Material Compatibility: Exhibits excellent matching performance with BN (boron nitride) coating—after coating, it has a strong anti-sticking effect, reducing the cleaning workload and extending the service life.

Technical Parameters (High Silicon 140 Hat Plate)

| Item | Technical Index |

| Density | 1.4-1.5 g/cm³ |

| Compression Strength | 15-16 Mpa |

| Thermal Expansivity | 4-4.5×10⁻⁶/℃ |

| Maximum Working Temperature | >1000℃ |

| Service Life | 450-800 casting cycles |

Matching Components & Application Scenarios

1. Key Matching Components of Hot-top Casting System

The hot-top casting hat plate needs to be used in conjunction with the following core components to form a complete molten aluminum control system:

- Casting Thimble: Controls the on-off and flow rate of molten aluminum;

- Distribution Plate: Uniformly distributes molten aluminum to each casting channel;

- Transition Plate: Connects the hat plate and distribution plate to ensure smooth flow transition;

- Graphite Ring: Enhances sealing and wear resistance at the connection;

- Distribution Launder: Transports molten aluminum to the casting mold.

2. Application Scenarios

- Suitable for hot-top casting processes of aluminum ingots, high-precision aluminum rods and aluminum profiles;

- Compatible with aluminum alloy casting of 3-20 inch diameters (covers common alloy specifications in industrial production);

- Applicable to high-end aluminum casting fields such as aerospace aluminum materials, new energy vehicle lightweight aluminum parts, and high-precision electronic aluminum substrates;

- Adaptable to large-scale continuous casting production lines, especially matching Wagstaff air slip casting units for efficient casting.

Product Advantages

- Quality Improvement: The non-peeling material structure and non-polluting performance effectively reduce inclusions in molten aluminum, increasing the qualification rate of aluminum alloy products by ≥15%.

- Cost Savings: Long service life (4-8 times that of ordinary silica-based hat plates) and low maintenance cost, significantly reducing the frequency of component replacement and production downtime.

- Thermal Stability: Good thermal shock resistance, can withstand rapid temperature changes during casting startup and shutdown, avoiding cracking and extending the service cycle.

- Energy Efficiency: The optimized structural design and high thermal insulation performance reduce heat loss of molten aluminum, saving energy consumption in the casting process by about 8-12%.

Specification & Packaging

1. Specification (Based on Alloy Diameter)

| Applicable Alloy Diameter | 3in | 3.5in | 4.5in | 5in | 5.5in | 6in | 6.5in | 7in |

| 8in | 9in | 10in | 12in | 14in | 16in | 18in | 20in | |

| Custom specifications can be provided according to customer’s casting equipment drawings and process requirements. |

2. Packaging

- Standard packaging: 30 pieces/carton (with anti-collision foam lining to prevent damage during transportation);

- Custom packaging: Can be customized according to customer’s batch quantity and transportation needs (such as wooden cases, pallet packaging).

Installation & Operation Instructions

- Component Selection: According to the diameter of the cast aluminum alloy and the model of the hot-top casting equipment, select the hat plate and matching thimble, distribution plate of corresponding specifications.

- Assembly Requirements: Install the distribution plate, hat plate, transition plate, distribution launder and graphite ring on the upper part of the casting platform; fix the thimble, transition plate and graphite ring on the lower part. Ensure all components are smooth, clean, free of cracks or damages, and the connections are seamless.

- Sealing & Insulation: Use ceramic fiber blanket or ceramic fiber paper to seal the gaps around the side and bottom of the components, enhancing thermal insulation effect and preventing molten aluminum leakage.

- Preheating Operation: After assembly, uniformly preheat the hot-top casting platform to 260℃-350℃. If electric heating is not available, flame heating can be used (note: direct flame heating on the lining of the hat plate and other components is strictly prohibited to avoid material damage). Preheating aims to remove adsorbed crystal water in the components and prevent thermal shock when molten aluminum is introduced.