Products

Categories

Message

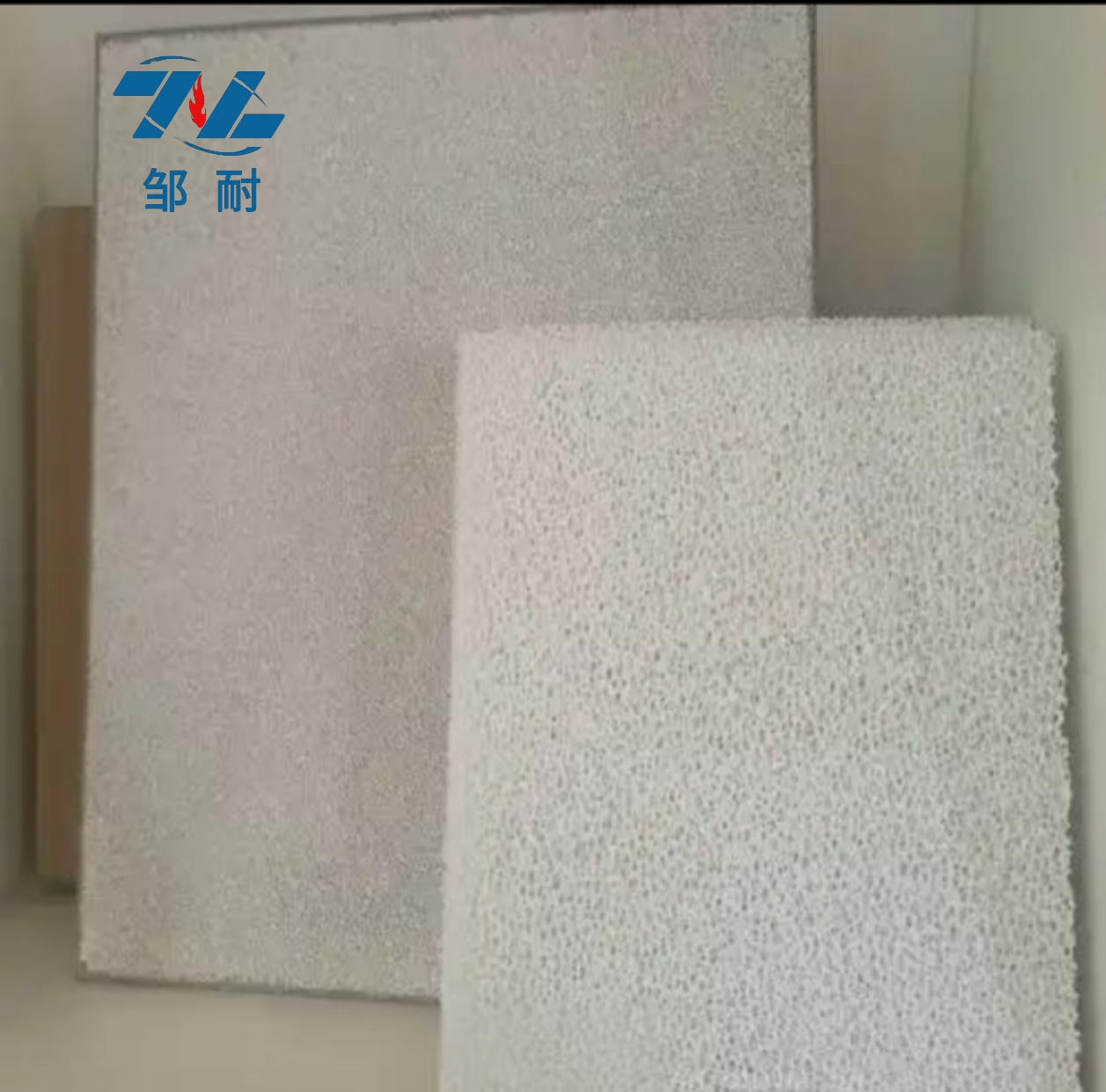

Aluminum liquid ceramic filter plate

Products Description

About This Project

Shandong Jinyi New Material Co., Ltd. (abbreviated as JINYI), a leader in molten aluminum purification technology since 2014, specializes in the R&D, production, and marketing of high-performance Alumina Ceramic Foam Filters (CFF, PAL series) for aluminum alloy casting. Integrating its core expertise in high-silicon melting and molten aluminum purification, JINYI’s ceramic foam filters have been widely recognized by global customers and applied in high-precision aluminum alloy production—including printing PS baseboards, canning materials, flexible packaging foils, rail transit aluminum components, aerospace parts, and wire & cable materials—delivering reliable impurity removal solutions for high-value-added aluminum processing.

Assemblies of JINYI Ceramic Foam Filter (PAL Series)

- Core Component: Alumina Ceramic Foam Filter (CFF)

- Sealing Accessory: Ceramic Fiber Sealing Gasket

- Matching Equipment: Filter Bowl (customizable for JINYI plate-type filter units)

Application of JINYI Ceramic Foam Filter

JINYI’s ceramic foam filter is manufactured via a precision-controlled process, leveraging a reticular-structured organic foam carrier:

- The carrier is immersed in thixotropic alumina slurry (formulated with JINYI’s proprietary high-purity alumina powder).

- An automatic extrusion process (square-to-center calibration) ensures uniform slurry deposition on the foam skeleton.

- After drying and solidification, the carrier is sintered at 1180℃ to form the final high-strength ceramic filter.

Installed in a matching filter bowl, the filter is dedicated to removing impurities from molten aluminum alloy. It meets the strict purification requirements of high-tech, high-value-added aluminum casting scenarios, such as:

- Precision components: Computer hard drive aluminum casings, turbojet engine fan blades

- High-end materials: Printing PS baseboards, food-grade canning aluminum sheets

- Industrial parts: Rail transit bogie aluminum alloy castings, automotive lightweight aluminum components

Core Advantages of JINYI Ceramic Foam Filter

- Efficient Impurity Removal: Adopts advanced adsorption principles—effectively captures large inclusions (≥100μm) and adsorbs tiny particles (down to 5μm)—ensuring molten aluminum purity.

- Zero Secondary Contamination: High sintering density (0.45g/cm³) prevents filter chipping or powder shedding, avoiding molten aluminum pollution.

- Superior Environmental Adaptability: Excellent thermal shock resistance (withstands rapid temperature changes from 260℃ to 1350℃) and molten metal erosion resistance, suitable for long-term high-temperature operation.

- Precision Manufacturing: Automated production lines with 3-level calibration procedures (dimension, pore density, slurry uniformity) ensure tight size tolerance (±3mm) and perfect fit with filter housings.

- Enhanced Product Quality: Improves the surface finish of cast aluminum parts, reduces internal defects (e.g., porosity), and enhances mechanical properties (tensile strength, ductility) of final products.

- Synergy with JINYI Systems: Optimized for use with JINYI’s plate-type filter units—compatible with the unit’s high-silicon lining and heating system, maximizing overall purification efficiency.

Sealing Gaskets for JINYI Ceramic Foam Filter

Ceramic fiber sealing gaskets are installed between the filter and filter bowl to prevent molten aluminum leakage at the interface. JINYI offers three gasket types, each tailored to specific application needs:

| Gasket Type | Material | Key Features | Applicable Scenarios |

| Fiber Paper Gasket | High-purity ceramic fiber paper | Thin, lightweight, easy to install | Small-size filters (7in-12in) for low-volume casting |

| Fiber Cotton Gasket | Dense ceramic fiber cotton | Good elasticity, moderate heat resistance | Medium-size filters (15in-20in) for general precision casting |

| Expanding Cotton Gasket | Expandable ceramic fiber | High expansion rate (activates at 450-550℃), excellent sealing | Large-size filters (23in-26in) for high-pressure molten aluminum flow |

Specifications of JINYI Ceramic Foam Filter

1. Standard Dimensions

- Square Sizes (length × width × thickness, tolerance: ±3mm for length/width, ±2mm for thickness):

7×7×50mm, 9×9×50mm, 12×12×50mm, 15×15×50mm, 17×17×50mm, 20×20×50mm, 23×23×50mm, 26×26×50mm

- Bevel Angle: 17.5° ±1.5° (optimized for seamless fit with filter bowl)

2. Custom Dimensions

Supports non-standard shapes and sizes based on customer needs:

- Shapes: Rectangular, round, trapezoidal, irregular (matching special filter bowls)

- Thickness: 30mm-80mm (adjustable for different filtration flow requirements)

Technical Parameters

| Parameter Category | Index Details |

| Density | 0.45 g/cm³ |

| Rupture Modulus (816℃) | 5.5 Mpa |

| Comprehensive Strength | 0.8-1.0 Mpa |

| Maximum Operating Temperature | 1350℃ |

| Sealing Gasket Activation Temperature | 450-550℃ (for expanding cotton type) |

| Pore Density (PPI) | 10/20/30/40/50/60 (pores per inch, tolerance: ±2 pores) |

Filtration Performance

JINYI ceramic foam filters achieve different filtration precision based on pore density (PPI), with the following performance metrics:

| Pore Density (PPI) | Removable Inclusions Diameter | Filtration Efficiency | Applicable Scenarios |

| 10 | ≥80μm | 78% | Rough filtration for low-purity aluminum |

| 20 | ≥40μm | 85% | General precision casting (canning materials) |

| 30 | ≥20μm | 88% | Printing PS baseboards, flexible packaging |

| 40 | ≥10μm | 92% | Automotive aluminum parts |

| 50 | ≥5μm | 95% | Aerospace components, computer casings |

| 60 | ≥5μm | 96% | Ultra-precision casting (turbojet parts) |

Filtration Flow Range (by Filter Size)

- 7in (178×178×50mm): 22-56 kg/min (effective filtration area: 75%)

- 12in (305×305×50mm): 50-156 kg/min (effective filtration area: 80%)

- 17in (432×432×50mm): 110-335 kg/min (effective filtration area: 86%)

- 23in (584×584×50mm): 210-640 kg/min (effective filtration area: 89%)

- 26in (660×660×50mm): 276-830 kg/min (effective filtration area: 90%)

Inspection Methods for JINYI Ceramic Foam Filter

To ensure product quality, JINYI implements a 3-step inspection process before delivery:

- Appearance Inspection: Check for cracks, chips, or uneven slurry coverage on the filter surface; reject products with visible defects.

- Dimension & Tolerance Check: Use digital calipers to verify length, width, thickness, and bevel angle—ensure compliance with ±3mm/±2mm/±1.5° tolerances.

- Pore Density Test: Randomly sample 3 filters per batch, count pores in a 25.4mm (1in) length, and confirm PPI matches the order requirement (±2 pores).

Packaging Specifications

JINYI adopts moisture-proof, shock-resistant packaging to protect filters during transportation:

| Filter Size (in) | Quantity per Case | Cases per Pallet | Total per Pallet | Pallet Dimensions (mm) | Pallet Gross Weight (kg) |

| 7-9 | 10 pcs | 20 cases | 200 pcs | 1100×1100×1400 | 220-310 |

| 12-15 | 5 pcs | 24 cases | 120 pcs | 1100×1100×1540 | 430-450 |

| 17-20 | 5 pcs | 18 cases | 90 pcs | 1100×900×1720 | 470 |

| 23-26 | 4-5 pcs | 8-12 cases | 48-60 pcs | 950×950×2050-2200 | 490-510 |

All packaging uses food-grade moisture-proof film and reinforced cardboard boxes; pallets are fumigation-free (compliant with ISPM 15).

Operating Instructions

- Pre-Installation Preparation: Clean the filter bowl surface to remove slag or residual aluminum; ensure no scratches or deformations on the sealing interface.

- Filter Installation: Gently place the ceramic foam filter into the bowl, press the surrounding sealing gasket by hand to ensure tight contact (avoid damaging the filter).

- Preheating: Use electric heaters or gas burners to preheat the filter and bowl evenly for 15-30 minutes; target temperature: ≥260℃ (expanding gaskets activate at 450-550℃). Avoid direct flame contact with the filter to prevent local overheating.

- Molten Aluminum Filtration:

- Initial molten aluminum height: 100-150mm (ensures stable flow).

- During filtration: Maintain flow rate within the filter’s specified range (e.g., 22-56 kg/min for 7in filters); avoid excessive flow (causes filter damage) or insufficient flow (reduces efficiency).

- Monitor aluminum height: It will drop to 75-100mm initially, then rise slowly—stop filtration if height drops below 75mm.

Post-Filtration: After use, promptly remove the filter from the bowl, clean residual slag from the bowl, and store the bowl in a dry place.

Storage Requirements

- Environment: Store in a ventilated, dry area (relative humidity ≤60%); avoid moisture, direct sunlight, or high-temperature environments.

- Handling: Do not stack heavy objects on filters; keep cartons upright to prevent filter deformation.

- Shelf Life: 12 months from the production date (when stored as required).

Note: If filters absorb moisture (e.g., soft texture, weight gain), re-dry them at 120℃ for 2 hours before use to avoid cracking during preheating.