Products

Categories

Message

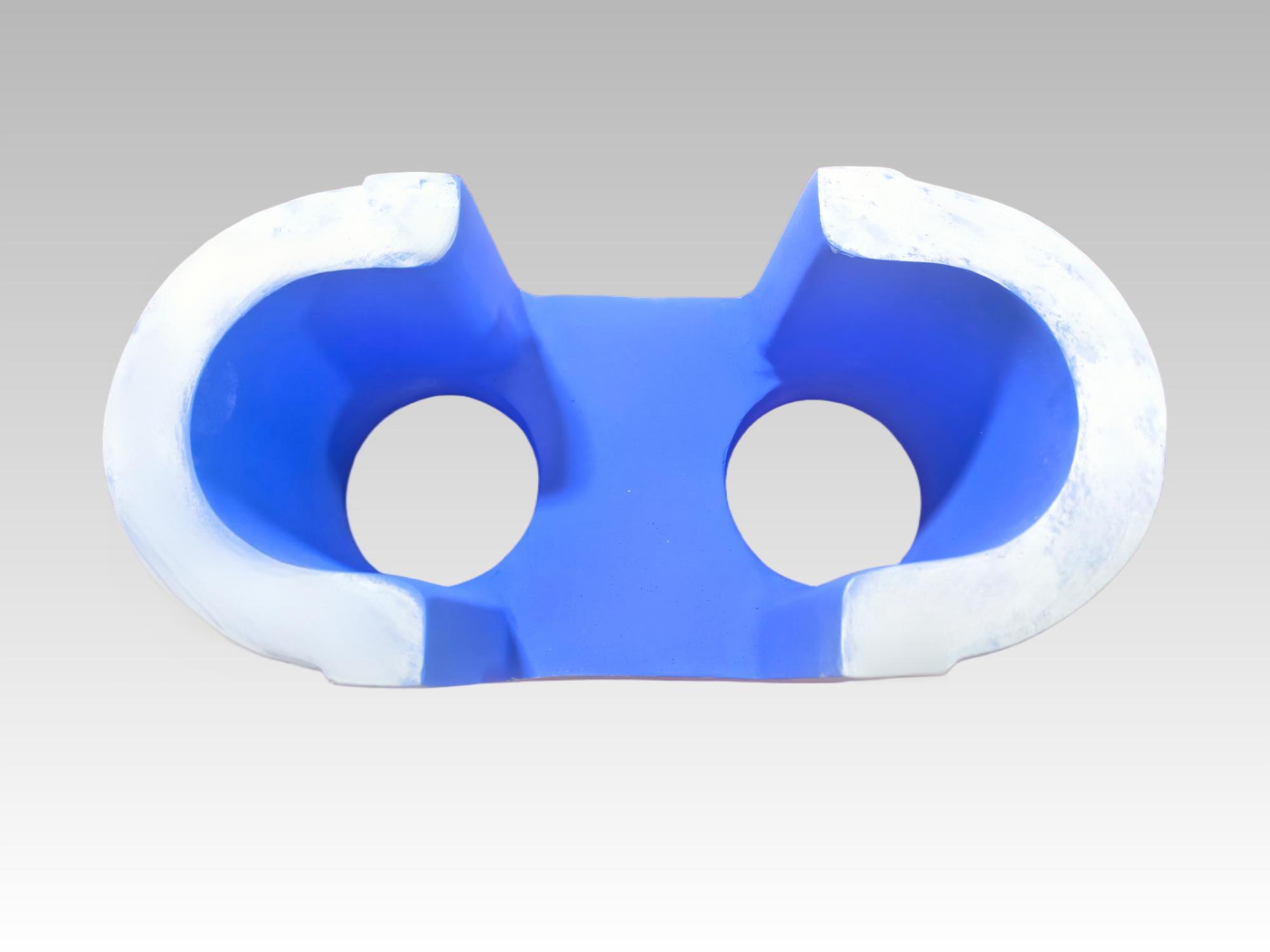

Aluminum liquid distribution plate

Category LAUNDER SERIES

Products Description

About This Project

Shandong Jinyi New Material Co., Ltd. (JINYI), a leader in molten aluminum solutions since 2012, specializes in aluminum liquid distribution launders—key for connecting integrated launders and casting molds. Engineered with proprietary high-silicon material, it focuses on uniform distribution and stable temperature preservation, widely used in high-value fields (micron aluminum foil, automotive alloys, PS baseboards) and recognized for low temperature drop, long life, and precise control.

Core Components & Advantages

| Component | Core Specs & Function |

| High-Silicon Liner | SiO₂≥98.5% (vacuum sintered), 1℃/m temperature drop, non-stick (BN coating: adhesion ≤0.2%), 180-360 days life |

| Distribution Plate | Al₂O₃≥95% ceramic, flow deviation ≤3%, uniform multi-mold feeding |

| SiN Thimble | ≤1350℃ resistance, ≥1 year life, anti-leakage |

| Transition Plate | 304 stainless steel + ceramic insulation, 15° bevel (anti-splash) |

Key Advantages

- Ultra-low temperature drop (≤1℃/m) for stable casting quality

- Long life (liner 180-360 days; plate/thimble ≥1 year)

- No secondary contamination (heavy metal-free, GB/T 38437-2020 compliant)

- Customizable (curved: R≥800mm; 2-8 outlets)

Technical Parameters (Key)

| Item | Value |

| Max Operating Temp | ≤1340℃ |

| Liner Density | 1.8-2.0 g/cm³ |

| Standard Length | 200-3000mm |

| Flow Rate Range | 0.3-0.8 m/s |

Application Scenarios

- Multi-station casting (2-8 molds: foil, ingots)

- Precision casting (micron foil, PS baseboards)

- Automated lines (with JINYI degassers/filters: automotive wheels, aerospace parts)

Operation & After-Sales

Simple Operation

- Install: Align (error ≤0.3mm/m) + ceramic seals

- Preheat: Electric (700-800℃) or flame (avoid direct contact)

- Maintain: Clean with wood scraper; BN coating every 15 days

Warranty & Service

| Component | Warranty Period |

| Liner | 60 days |

| Plate/Thimble | 6 months |

| Transition Plate | 1 year |

Compatibility

Fits JINYI integrated launders (500-3000mm), degassers (15-65 MT/H), filters (15-26in). Customize with:

- Mold quantity/size 2. Flow rate 3. Layout (straight/curved) 4. Alloy type