Products

Categories

Message

Aluminum Liquid Online Degassing Unit

Products Description

About This Project

Shandong Jinyi New Material Co., Ltd. (abbreviated as JINYI), since 2014, has been dedicated to new material R&D and the production of high-precision online molten aluminum degassing units. With a professional R&D team boasting over 10 years of experience in new materials and degassing equipment, JINYI has obtained more than 15 national patents, and its online molten aluminum degassing units have won wide recognition and positive feedback from customers in both domestic and overseas markets (including Southeast Asia, Europe, and North America).

JINYI’s online molten aluminum degassing unit adopts advanced high-silicon melting technology, which significantly extends the overall service life of the equipment. Among its core components, the degassing rotor, heater protection thimble, and thermocouple protection thimble all use ceramic manufacturing technology—this ensures compliance with the strict requirements of high-precision aluminum production and provides reliable equipment support for molten aluminum purification.

Installed between the melting furnace and casting equipment, this unit’s core function is to remove hydrogen (H) and slag from molten aluminum. It integrates dual functions of molten aluminum processing and heating, mainly serving the high-precision molten aluminum purification industry (e.g., automotive aluminum alloy parts, high-precision aluminum profiles, aluminum foil for packaging, and aerospace aluminum materials) to help downstream enterprises improve the quality of aluminum products.

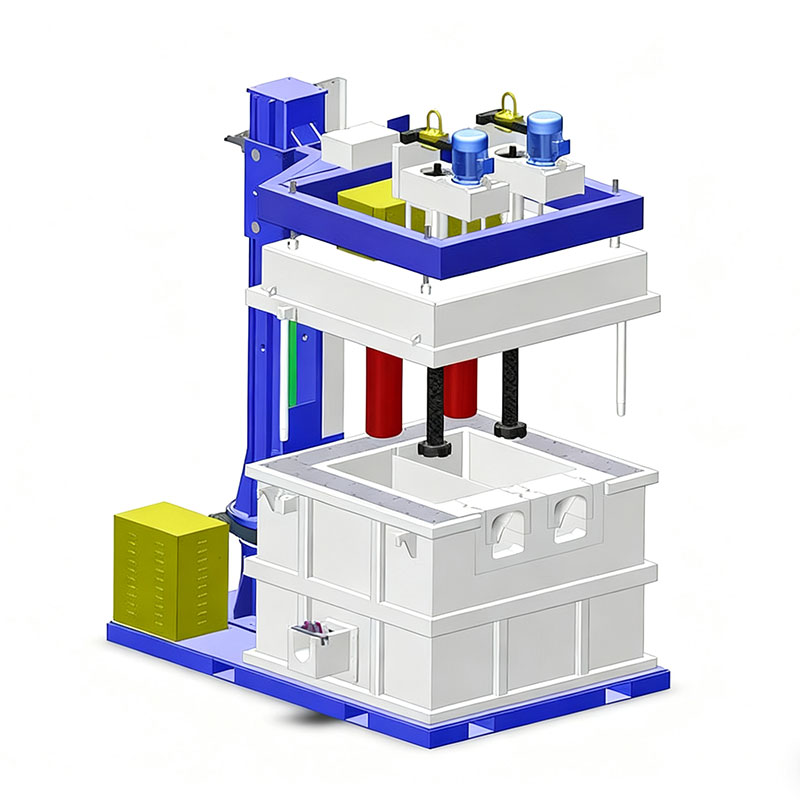

Assembling of Online Degassing Unit

- Mechanical Drive System

- Degassing Box & Cover

- Rotor & Heater

- Electric Control System

- Cooling System (for heat dissipation of electric components and rotor drive, ensuring stable operation at high temperatures)

Parameters of Online Degassing Unit

| Parameter Item | Specification 1 | Specification 2 | Specification 3 |

| Max Degassing Flow (MT/H) | 15 MT/H | 35 MT/H | 65 MT/H |

| Degassing Box Standard | 1 Chamber 1 Rotor (1B1R) | 2 Chambers 2 Rotors (2B2R) | 3 Chambers 3 Rotors (3B3R) |

| Degassing Box Structure | 1 Drain Outlet + 1 Slag Outlet | 2 Drain Outlets + 1 Slag Outlet | 3 Drain Outlets + 1 Slag Outlet |

| Lifting System | Hoisting Type | Rotor Mechanical Lifting | Cover Hydraulic Lifting |

| Power Supply | 380V/50Hz (3-phase) | 380V/50Hz (3-phase) | 380V/50Hz (3-phase) |

| Working Temperature Range | 720°C – 850°C | 720°C – 850°C | 720°C – 850°C |

| Inert Gas Flow Range (Processing Stage) | 10-15 L/min | 15-20 L/min | 20-25 L/min |

Online Degassing Unit Performance

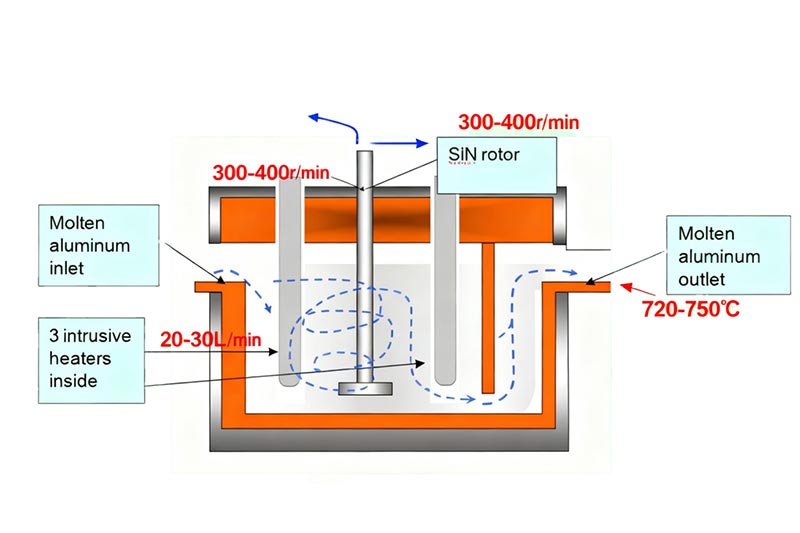

JINYI’s online molten aluminum degassing unit is mainly used to remove hydrogen (H) and slag from molten aluminum, operating on the gas flotation principle: The degassing rotor injects inert gas (e.g., argon) or a mixture of chlorine and inert gas into the molten aluminum, crushing the gas into dispersed tiny bubbles. As the bubbles rise to the surface of the molten aluminum, three key processes are completed simultaneously:

- Bubbles absorb hydrogen (H) in the molten aluminum and carry it away as they float upward, achieving hydrogen removal.

- Chlorine reacts chemically with alkali metals in the molten aluminum to form chlorides, which are separated and removed along with bubbles or slag.

- Bubbles adsorb and carry slag in the molten aluminum upward, completing slag removal.

Key Component Design Standards

1. Degassing Efficiency

The average degassing efficiency of JINYI’s online molten aluminum degassing unit reaches 60%. When argon (Ar) is used as the degassing gas and the magnesium (Mg) content in the molten aluminum is ≤1%, the hydrogen content in the molten aluminum after degassing can be as low as 0.09cc/100g—meeting the purity requirements for high-precision aluminum production.

2. Lining Structure

The lining of the degassing box is made of high-silicon molten material, with an average service life of 2-3 years. It features aluminum-non-adhesion and no secondary pollution, ensuring the purity of the molten aluminum. A float stopper is installed inside the lining to effectively prevent oxides from mixing into the molten aluminum and avoid bubbles or slag overflowing from the box, ensuring stable degassing.

3. Degassing Rotor

The rotor is made of silicon nitride (SiN), with an average service life of 2-5 years. It exhibits excellent performance in corrosion resistance, thermal shock resistance, oxidation resistance, wear resistance, and mechanical strength. With a shaft diameter of 60mm and a head diameter of 200mm, its optimized size design reduces the resistance of molten aluminum during stirring. The rotational speed is designed to be 450-550 R/M, which can fully crush gas and disperse it evenly into the molten aluminum—offering significant cost advantages for long-term use.

4. Intrusive Heater Protection Thimble

Also made of silicon nitride (SiN), it has an average service life of 1-2 years. It features high heating efficiency, effective prevention of oxidation and slagging, and no molten aluminum pollution—providing dual protection for the stable operation of the heater and the quality of the molten aluminum.

5. Gas Protection Design

The unit supports mixed gases of argon (Ar), nitrogen (N₂), and chlorine as degassing media. A dedicated gas protection scheme is also equipped to ensure stable gas injection and improve degassing efficiency. The gas flow can be adjusted steplessly according to the molten aluminum composition and production requirements.

6. Sealing Structure Design

The sealing structure covers the cover, lining, inlet, and outlet. It effectively prevents slag infiltration or gas leakage, further improving degassing efficiency and ensuring the sealing and stability of equipment operation.

Operation Schematic Diagrams & Operation Specifications

Operation Specifications:

- After the degassing box is heated, turn off the heating unit. When the heater temperature is close to the molten aluminum temperature, inject inert gas into the rotor and introduce molten aluminum into the box.

- Check the sealing between the inlet/outlet and the launder to ensure no leakage.

- Check the cone at the heat-protection drain outlet at the bottom of the box to confirm its normal status.

- Detect the molten aluminum temperature (minimum 720°C); adjust the molten aluminum height to be 3cm away from the bottom of the launder to facilitate observation of molten aluminum entering the box.

- The operator shall wear protective equipment (e.g., high-temperature-resistant gloves, face shield) before closing the cover. When molten aluminum flows into the box, slag on the surface can be skimmed through the slag outlet.

- Start production when the molten aluminum temperature rises to 780°C; close the slag outlet for heat preservation.

- During the heat preservation stage, molten aluminum can be retained in the box at the set temperature, and no molten aluminum processing is required at this stage.

- Continuously inject inert gas into the rotor to prevent molten aluminum from blocking the gas outlet.

- Immediately turn on the heater and set the heat preservation parameters after the molten aluminum has fully flowed into the box.

- Start the heating system to control the molten aluminum temperature; monitor the gas flow rate. Switch the rotor speed from the heat preservation stage to the processing stage. At the same time, increase the inert gas flow into the rotor and switch the gas flow rate from the heat preservation stage to the processing stage.

- The operator sets the molten aluminum heating temperature and maintains a stable degassing condition.

- Emergency Shutdown: In case of abnormal phenomena (e.g., excessive molten aluminum temperature, gas leakage, or abnormal rotor noise), press the emergency stop button immediately, cut off the gas supply, and drain the molten aluminum in the box according to the emergency procedure.

After-sales Service

JINYI provides a nationwide after-sales service network, offering 24-hour technical consultation, on-site maintenance, and spare parts supply services. For overseas customers, JINYI has established cooperative after-sales service centers in key regions to ensure timely response to equipment maintenance needs and minimize production downtime for customers.

Application Fields

JINYI’s online molten aluminum degassing units are widely used in high-precision aluminum processing industries, including:

- Automotive: Production of lightweight aluminum alloy parts (e.g., engine blocks, wheel hubs).

- Construction: Manufacturing of high-precision aluminum profiles for curtain walls and doors/windows.

- Packaging: Processing of high-purity aluminum foil for food and pharmaceutical packaging.

Aerospace: Production of high-strength aluminum materials for aircraft components.