Products

Categories

Message

Caster Tip

Products Description

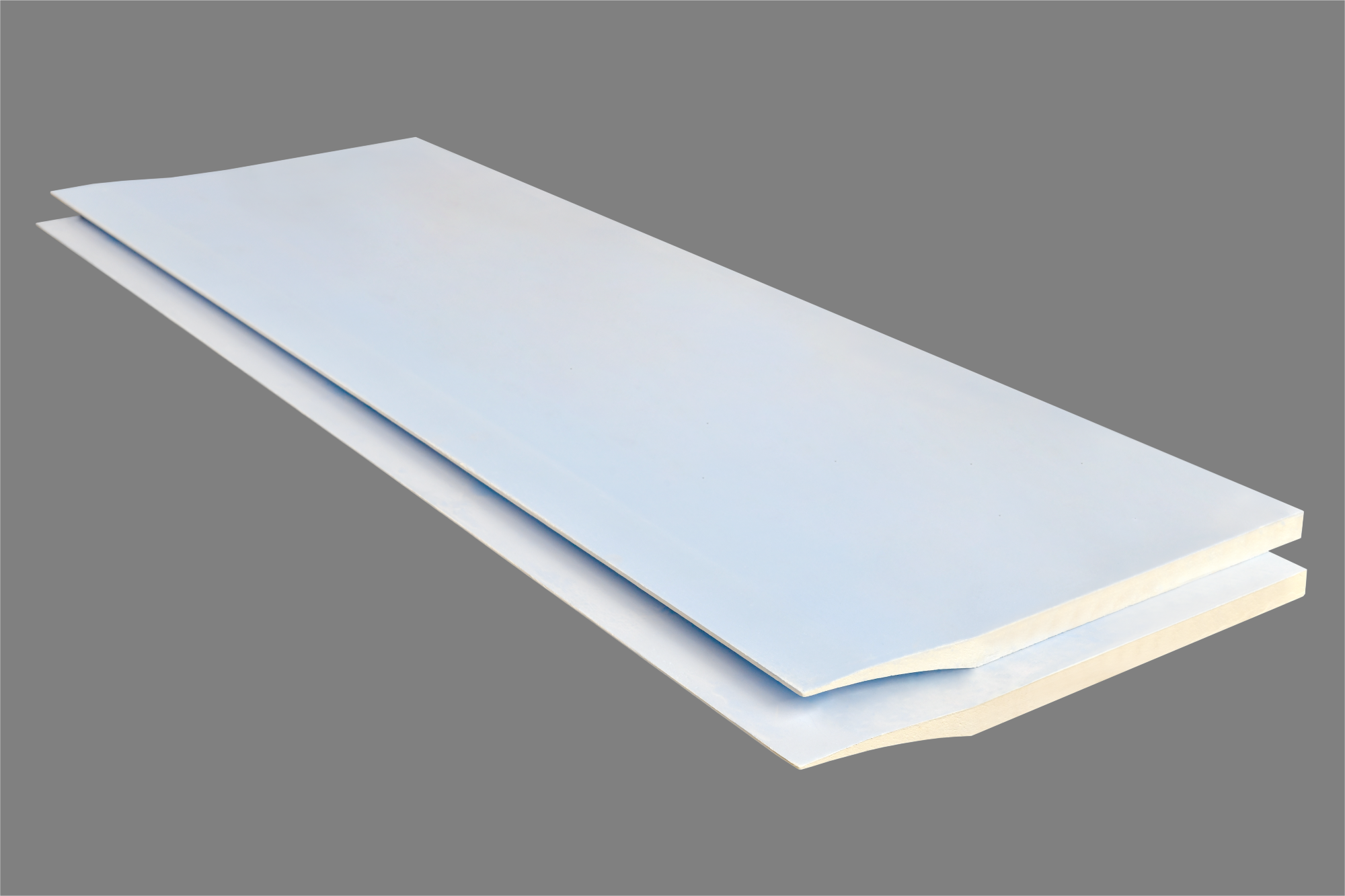

Shandong Jinyi Ceramic Caster Tip

1. Product Overview

Since its establishment, Shandong Jinyi New Materials Co., Ltd. has been dedicated to the research and production of high-precision ceramic casting nozzles. Its products have been widely recognized in the aluminum processing market both domestically and internationally. Our ceramic casting nozzles are the core components used for the casting of micro-aluminum foil and PS plates. They are used in conjunction with supporting components (gaskets, ears, flow control boxes, fixtures, transition nozzles) to ensure the stable crystallization and precise control of the molten aluminum. It is compatible with mainstream casting equipment and can meet the high-standard requirements of aluminum foil production.

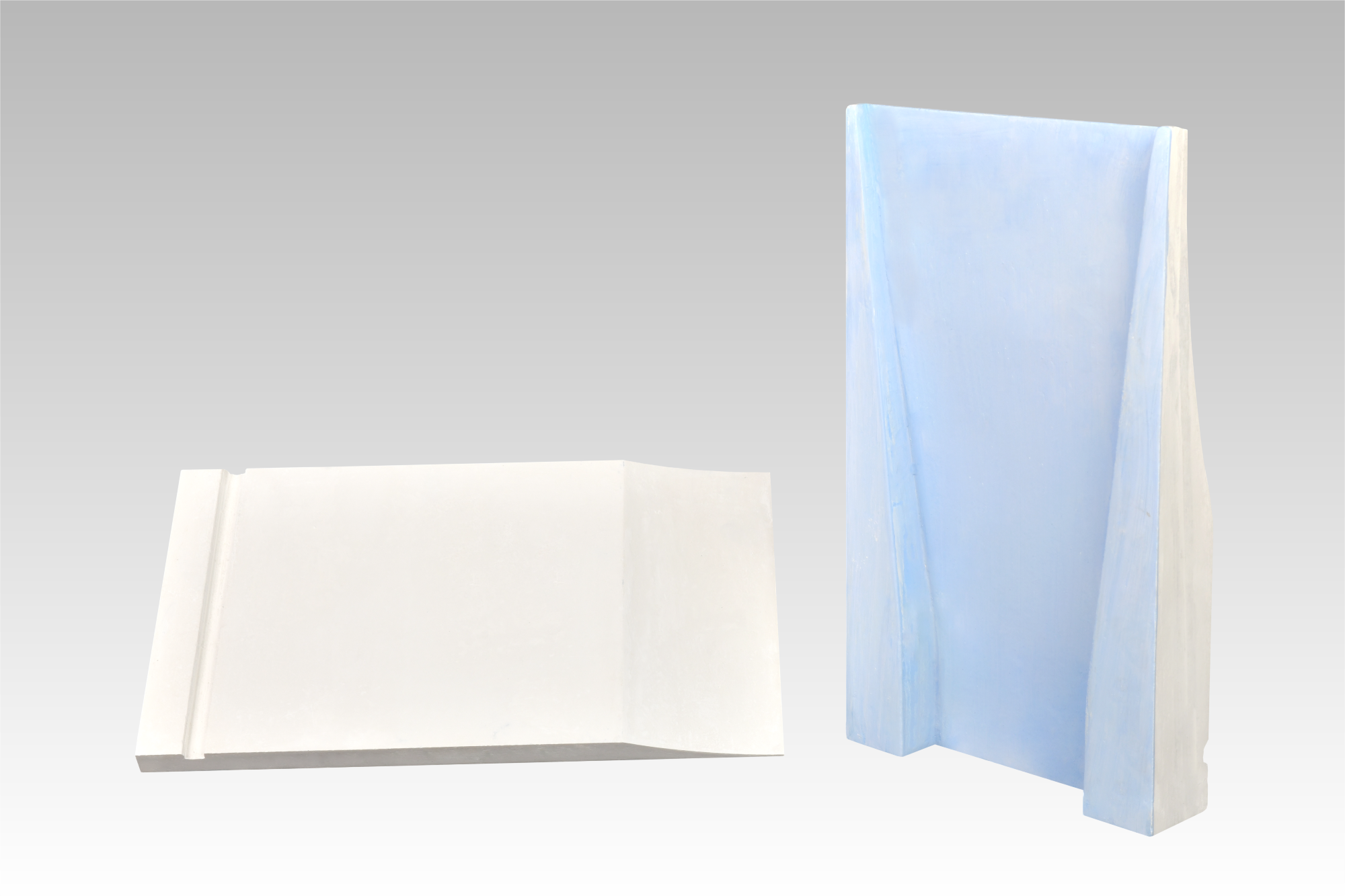

2. Core Material & Performance

- Material: Nano-grade fiber composite ceramic (with nano-paint coating)

- Key Traits:

- Uniform fiber distribution, proper density, and strong rigidity (no deformation)

- High dimensional accuracy, excellent oxidation resistance, and strong erosion resistance

- Good thermal insulation to stabilize casting parameters

- Protects aluminum foil surface (BN coating recommended for better anti-stick performance)

3. Specifications & Parameters

3.1 Dimensions (mm)

| Item | Value Range |

| Length | 200-2300 |

| Width | 50-600 |

| Thickness of Tip | 1.6-10 |

| R Radius | Constant value |

| Shape | Enterocoelia/Level |

3.2 Technical Parameters

| Item | Typical Value (Roll-PH) |

| Density (g/cm³) | 0.45-0.57 |

| Rupture Modulus (816℃, Mpa) | 42-48.8 |

| Thermal Expansivity (680℃, K⁻¹) | 1.35-1.56×10⁻⁶ |

| Thermal Conductivity (540℃, w/m·k) | 0.12-0.15 |

| Max Working Temperature | 1260℃ |

4. Product Advantages

- Meets molten aluminum mechanics requirements for high-precision foil casting

- Low deformation rate, effectively improving aluminum foil quality and qualification rate

- Nano-paint coating enhances erosion resistance, extending service life

- Good insulation stabilizes casting parameters, reducing production errors

5. Installation & Usage

- Cut and assemble per design drawings; ensure the caster tip is intact (no cracks or damage).

- Preheat: Heat the caster tip to target temperature for 2 hours, hold at 260℃ (Roll-PH) for 5 hours to remove crystal water, then cool to room temperature.

- Complete assembly with matching parts within 2 hours after cooling.

6. Packaging & Storage

- Packaging: 10 sets/wooden case (shock-proof, moisture-proof design)

- Storage: Keep in a ventilated, dry environment; avoid moisture and heavy loads on top.

Contact: Shandong Jinyi New Material Co., Ltd. | For customization or technical inquiries, contact our sales team.