Products

Categories

Message

Flow Control Bar and Flow Tube

Products Description

About This Project

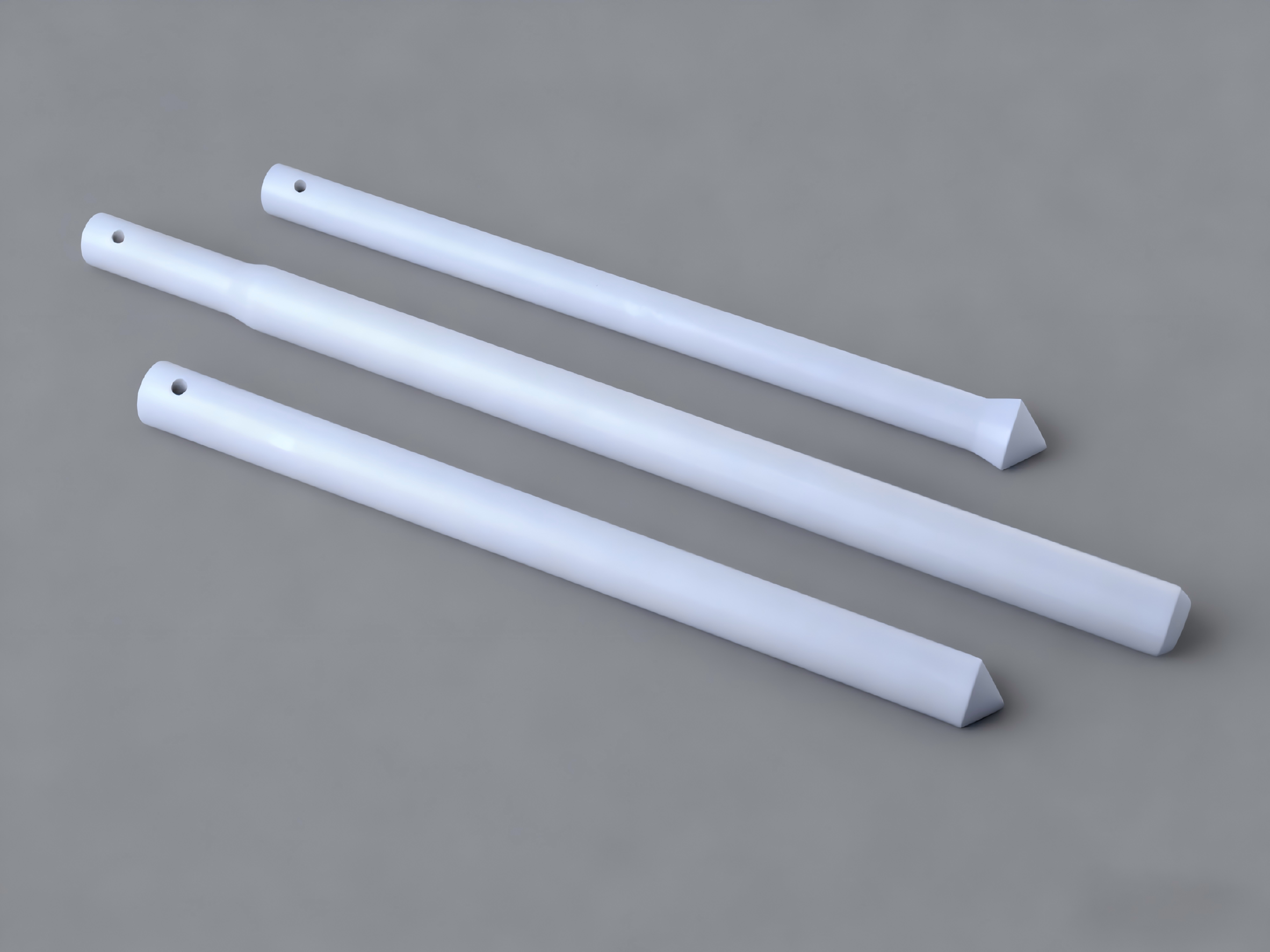

Flow Control Bar and Flow Tube

Shandong Jinyi New Material Co., Ltd. is a high-tech enterprise specializing in the R&D, production and application of functional ceramic materials. It focuses on providing high-performance flow control solutions for the aluminum casting industry. Since 2014, Jinyi has been committed to the research and development of molten aluminum flow control products, including flow control bars, flow tubes (also known as ceramic alumina tubes), float plates, tapping cones, graphite insulation sleeves, impurity filtration rings, etc. These products are designed to work in synergy, effectively stabilizing casting process parameters and realizing precise control of molten aluminum flow. They have won wide recognition from aluminum processing enterprises at home and abroad.

Jinyi’s Flow Control Bars and Flow Tubes are made of high-purity composite ceramic materials, which have excellent corrosion resistance and cause no pollution to molten aluminum. With good reusability, the products fully meet the requirements of high-value-added and high-tech aluminum casting processes (such as high-precision aluminum ingot casting and automotive aluminum alloy casting). Recommended Matching Products: Casting-RAL High-Temperature Sealant & Casting-RC Ceramic Fiber Gasket

Using Cooperatively:

- Flow Control Bar

- Flow Tube

- Dedicated Tube Holder

- High-Temperature Sealing Gasket

Features:

Jinyi’s Flow Control Bars and Flow Tubes are mainly used in low-pressure casting and gravity casting systems to adjust and stabilize the flow rate of molten aluminum. The flow control bar is also called a “stopper rod”, and the flow tube is commonly referred to as a “ceramic flow sleeve”. The products are sintered from high-purity SiO₂-Al₂O₃ composite materials, which possess characteristics such as high mechanical strength, strong resistance to molten aluminum erosion, good thermal shock stability and long service life. When used with a special BN (boron nitride) coating, they can achieve an excellent anti-adhesion effect with molten aluminum, preventing material blockage.

Advantages:

- Excellent material performance: High strength, strong erosion resistance, good thermal shock stability and a smooth surface to ensure stable flow;

- Long service life: When used with a BN coating, it can withstand 50-120 casting cycles, reducing the frequency of replacement;

- Convenient operation: Easy to install and disassemble, compatible with mainstream casting equipment;

- Energy-saving and efficient: Reduces heat loss of molten aluminum, lowering energy consumption by 8%-10% compared with traditional products;

- Environmental protection: No harmful substances are released during use, ensuring the purity of aluminum products.

Specification:

| Items | Dimensions | Special Dimensions | Package | Special Package |

| Flow Control Bar | 150-1300mm | Customized as per drawing | 50 pieces/box | Customized as required |

| Flow Tube | 120-700mm | Customized as per drawing | 50 pieces/box | Customized as required |

Instructions:

- Assemble the flow control bar and flow tube in strict accordance with the design drawing; before installation, ensure the product surface is smooth, clean, free of damage and gaps;

- Check the sealing performance between the tube holder and the launder; it is recommended to use high-density ceramic fiber paper or ceramic fiber blanket for sealing to prevent molten aluminum leakage;

- Match the controller system with the specifications of the flow control bar, and conduct pre-installation debugging to ensure correct assembly and that the flow control accuracy meets process requirements (flow rate error ≤ ±2L/min);

- After each casting cycle, clean the product surface with a dedicated tool, and reapply the BN coating if necessary to maintain the anti-adhesion effect.